Expendable Packaging

Del-Tec Packaging develops expendable packaging solutions tailored for one-way shipments and single-use distribution systems with an emphasis on efficiency, simplicity, and cost-effectiveness when these factors are paramount and upfront costs are critical. These systems are commonly used in distribution, kitting, and supply chains where reusable loops are impractical. The value in expendable packaging lies in its customization that protects products reliably, reduces handling complexity, and accelerates delivery while optimizing material costs, reducing weight, and packaging labor.

Typical expendable systems often include foam inserts or pads that are CNC cut, foam assemblies and end caps, edge profiles and corners, protective wraps or rolls, partitions and divider sets, along with corrugated and folding boxes. Materials such as polyethylene, polyurethane, plastic corrugated, and paper corrugated are employed in the development of comprehensive systems designed to deliver cushioning, surface protection, moisture resistance, and cost-efficiency. At Del-Tec, we combine decades of deep design experience and material knowledge, fabrication precision, and prompt prototyping to deliver expendable packaging solutions that minimize damage, lower freight cost, and get your product safely to its destination.

Assemblies

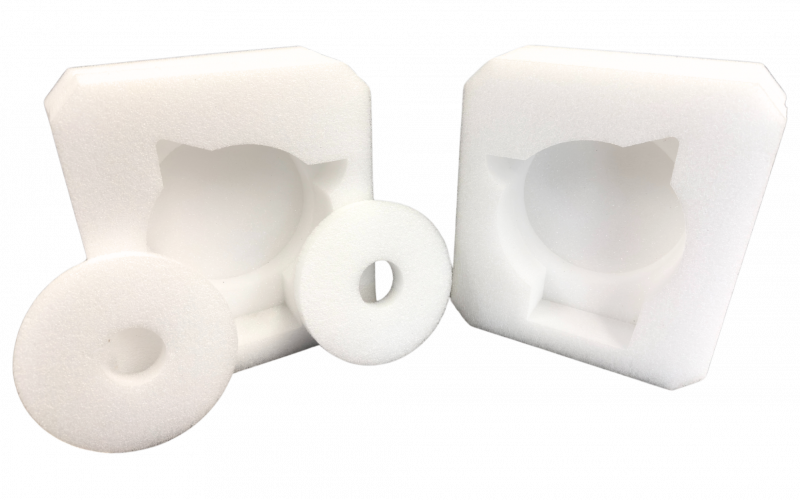

When precise fit and part protection are essential, our CNC Waterjet and Die-Cut foam and plastic inserts deliver precision protection through CAD-controlled cutting and engineered cutting die tools. We source a large variety of foam grades, including closed-cell foams for rugged protection, open-cell foams for lightweight cushioning, anti-static materials for sensitive electronics, and various densities to provide superior cushioning for your unique products. These inserts prevent part movement, absorb vibration and shock, and enhance presentation in finished packages while reducing excess material and shipping volume.

CNC Waterjet & Die-Cut

foam Inserts

When precise fit and part protection are essential, our CNC Waterjet and Die-Cut foam and plastic inserts deliver precise protection through CAD-controlled cutting and engineered cutting die tools. We source a large variety of foam grades, including closed-cell foams for rugged protection, open-cell foams for lightweight cushioning, anti-static materials for sensitive electronics, and various densities to provide superior cushioning for your unique products. These inserts prevent part movement, absorb vibration and shock, and enhance presentation in finished packages while reducing excess material and shipping volume.

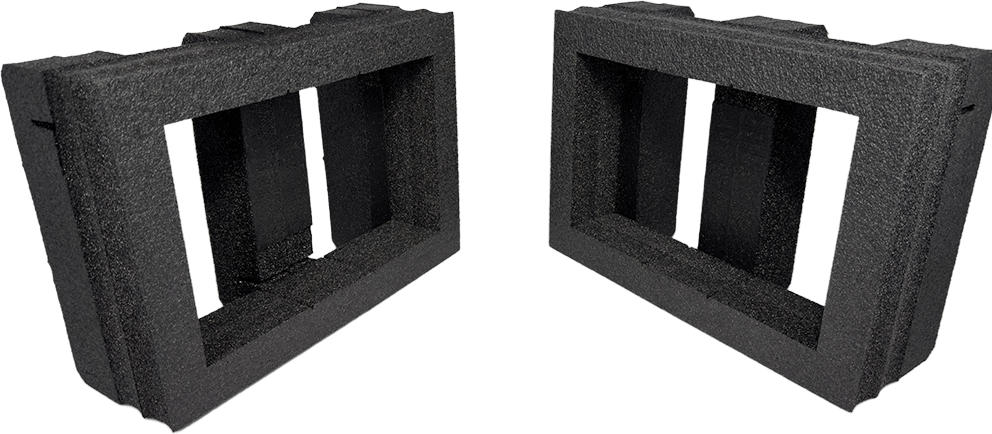

End Caps & Pads

Del-Tec’s custom foam end caps and pads are essential components in many expendable packaging solutions, designed in various foam grades and styles to provide lightweight yet highly effective protection during one-way transit. Foam pads, cut with our fully automated smart cutter, deliver precise, repeatable results across high-volume production runs without the need for costly tooling, making them an efficient and versatile option for protective packaging. These pads work seamlessly with our custom-engineered foam end caps, which are available in many styles and tailored to fit a wide range of product sizes and geometry requirements. End caps are designed to absorb compression loads, shield product faces, and redirect impact away from critical surfaces, ensuring products arrive safely and damage-free. Together, foam pads and end caps integrate effortlessly into packaging layouts, offering a cost-effective, customizable, and durable solution for even the most demanding shipping environments.

Edge Protectors & corners

Our edge protectors and foam corner guards reinforce the most vulnerable zones, edges and intersections by distributing impact forces and preventing abrasion or chipping. From fabricated custom foam to polyethylene profiles in U, L, or custom shapes, these components support strapping, stacking, and handling stresses while safeguarding finishes and maintaining lightweight efficiency. Available in various thicknesses, densities, and lengths, our edge protection systems easily integrate with existing packaging configurations as a lightweight solution preventing damage at critical stress points.

Partitions & Divider Sets

Packing multiple items in one box? Del-Tec’s divider and partition solutions use plastic and paper corrugated assembled with foam panels to segment, separate, and shield contents. These systems prevent contact between parts, distribute impact energy, and improve carton stacking strength. Ideal for fragile assemblies, bottle sets, or mixed SKUs, they also streamline packing operations and lower damage rates while using efficient, lightweight materials.

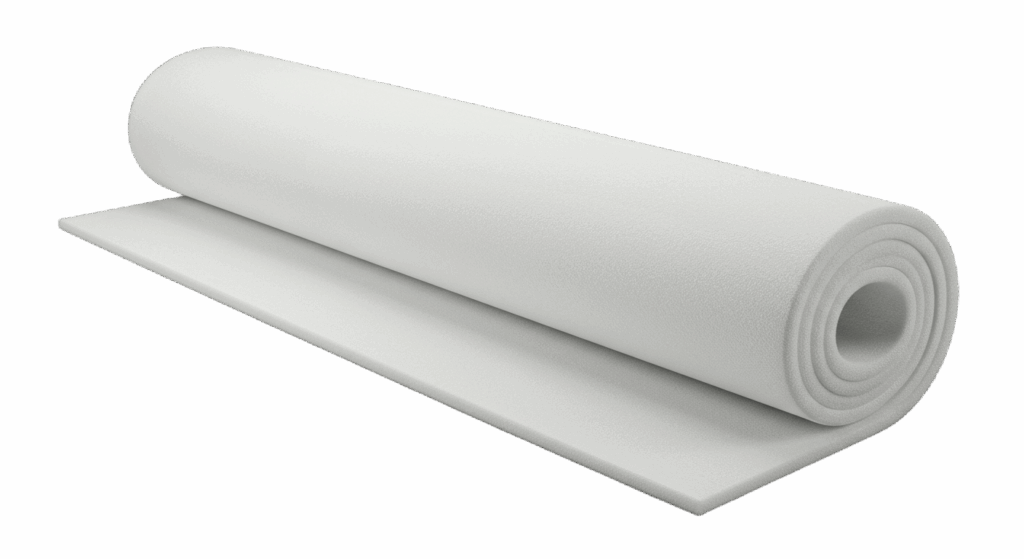

Protective Wraps & Rolls

Flexible, fast, and versatile, our protective wraps and rolls provide scratch and abrasion protection, surface cushioning, and light impact dampening for products of all shapes. Available as foam, plastic, or paper substrates, single and double-face styles are easy to cut and layer. These wraps are a go-to for inner pack protection, surface finishes, and protecting items during in-line or transit handling.

Corrugated Packaging

& Folding Boxes

Del-Tec delivers high-performance paper and plastic corrugated box packs that are lightweight yet offer reliable structural support and protection for shipping and storage. Utilizing high-grade flutes, precision scoring, and optional internal reinforcement, these cartons maintain strength while minimizing material. We offer box sizes customizable for your parts, with customization, printed branding, and foam insert and pad accommodations that ensure your package is both protective and presentation ready.