Safety Data

Polyethylene

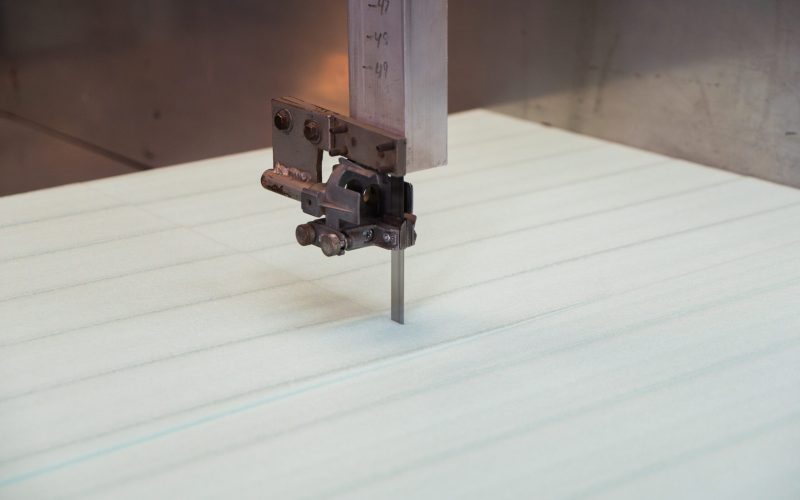

Polyethylene Foam: The Ideal Solution for Custom Packaging

Polyethylene (PE) foam is an ideal material for custom packaging solutions due to its lightweight, durable, and versatile properties. Its closed-cell structure provides excellent shock absorption, impact resistance, and water resistance, ensuring reliable protection for sensitive and high-value items during transit and storage. Additionally, polyethylene foam is chemically inert, making it suitable for various industries, including electronics, medical devices, and industrial equipment. With its ability to be fabricated into precise shapes and its recyclable nature, PE foam offers a cost-effective and environmentally friendly option for meeting diverse packaging needs.

Strengths & Weaknesses

- Strengths

- Impact Resistance: Absorbs shocks and vibrations effectively.

- Buoyancy: Highly buoyant, making it useful in marine applications.

- Chemical and Water Resistance: Resistant to most chemicals and moisture.

- Weaknesses

- Limited Thermal Resistance: Not ideal for high-temperature environments.

- Flexibility Variance: Lower density PE foams can be less flexible.

Applications

- Packaging: protective packaging for electronics, appliances, and delicate items.

- Construction: insulation boards, expansion joint fillers, and sealants.

- Automotive: interior padding, gaskets, and sound dampening materials.

- Medical: orthopedic supports, prosthetics, and padding.

- Consumer Products: Protective padding and safety devices.

- Electronics: foam inserts for shock absorption and protection.