Fabrication & Machinery

Del-Tec Packaging’s advanced fabrication capabilities and machinery push the boundaries of what’s possible in foam and plastic packaging. With a full suite of precision and automated processes, we turn complex designs into production-ready parts for industries ranging from aerospace and automotive to commercial and industrial systems. Our methods and machine capabilities below show a deeper look at each technique and how we leverage them to deliver superior accuracy, consistent performance, and high-quality products through our efficient manufacturing to meet optimal performance standards.

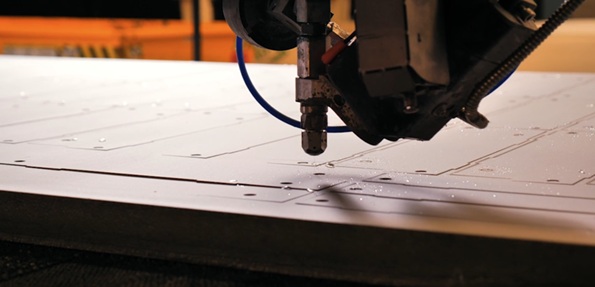

Waterjet Cutting

Del-Tec uses multi-axis water jet cutting to create precise packaging solutions tailored to your needs. This technique employs a high-pressure water stream to cut foam and plastic with clean edges and tight tolerances. Ideal for custom inserts and components, water jet cutting ensures accuracy without heat damage, making it perfect for protecting delicate or complex items.

watch video

Die Cutting

Die cutting is a high-precision process used by Del-Tec to produce consistent and accurate packaging components at scale. By pressing materials like foam or plastic against a custom-shaped die, we create uniform cuts and shapes with speed and efficiency with our fleet of 6 presses. This method is ideal for high-volume production of inserts, dividers, and other packaging elements, ensuring a perfect fit and reliable protection for your products.

CNC Routing

CNC routing is a versatile and precise fabrication technique used by Del-Tec to create custom packaging components. This computer-controlled process uses specialized tools to cut, carve, and shape foam, plastic, and other materials with exceptional accuracy. Ideal for creating intricate designs and complex geometries, CNC routing ensures a high-quality finish and a perfect fit for packaging solutions that protect delicate or uniquely shaped products.

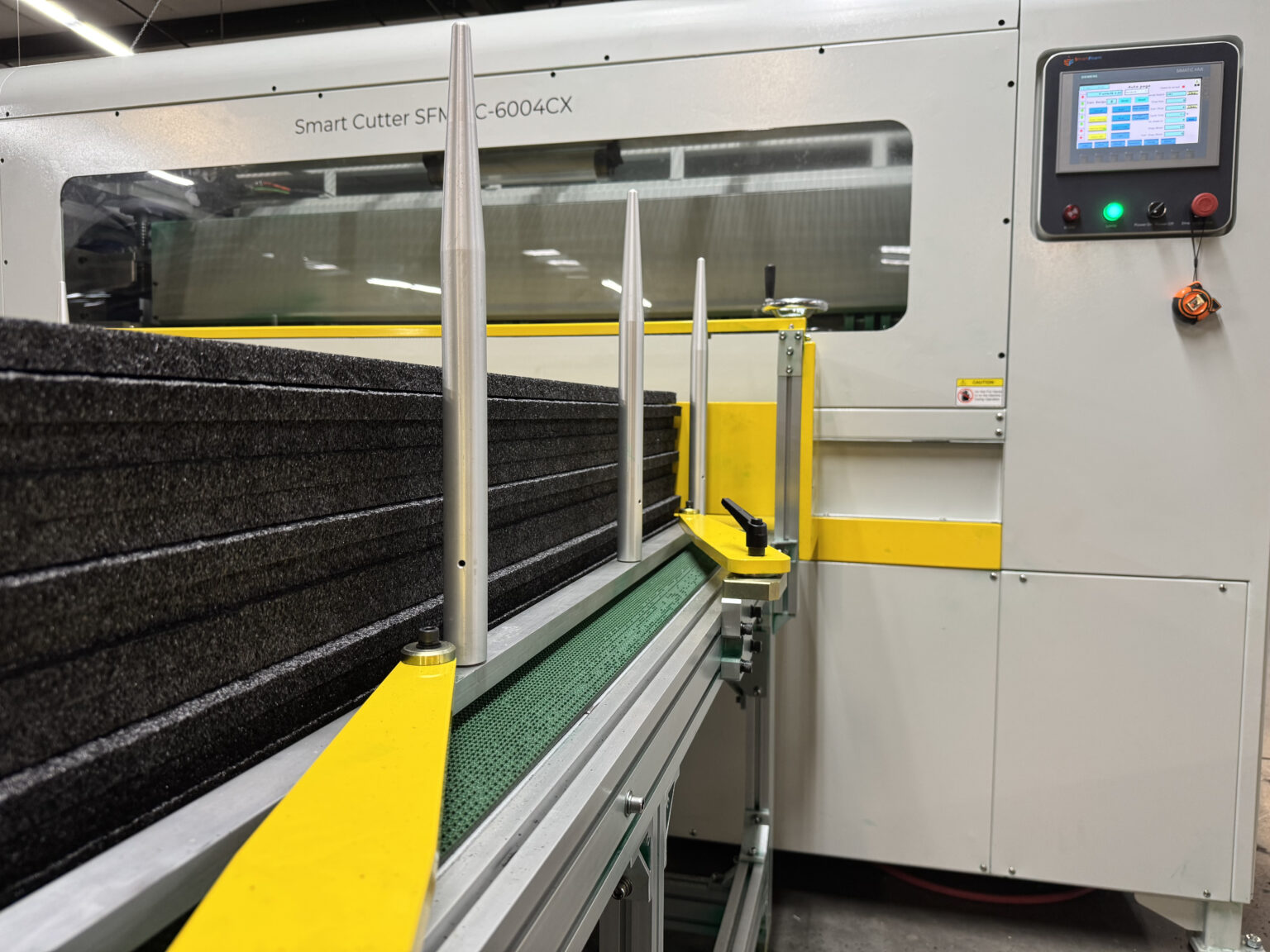

Automated Pad Cutting

Del-Tec’s fully automated Smart Cutter is designed for high-volume, precision cutting of foam pads with unmatched speed and consistency. Using an automated team of circular blades and finishing blade, the Smart Cutter produces clean, accurate cuts without the need for costly tooling or setup, making it ideal for large production runs. This process ensures repeatable results across a wide range of foam materials, including PE, XLPE, EPE, EVA, and PU, while maximizing efficiency and reducing waste. With its automation and high throughput, the Smart Cutter delivers reliable, ready-to-use pads that integrate seamlessly into our production of parts and material blanks, providing customers with a cost-effective and scalable solution for demanding shipping and manufacturing environments.

Automated Heat Welding

Our automated heat welding process applies controlled heat to bond flexible foam materials, creating durable assemblies, case inserts, end caps, and dunnage parts with excellent structural integrity. Del-Tec employs multiple (x2) automated heat welders used to build multi-layer inserts out of several types of foam types including XLPE, PE, EPE, EPP, and other various flexible foams.

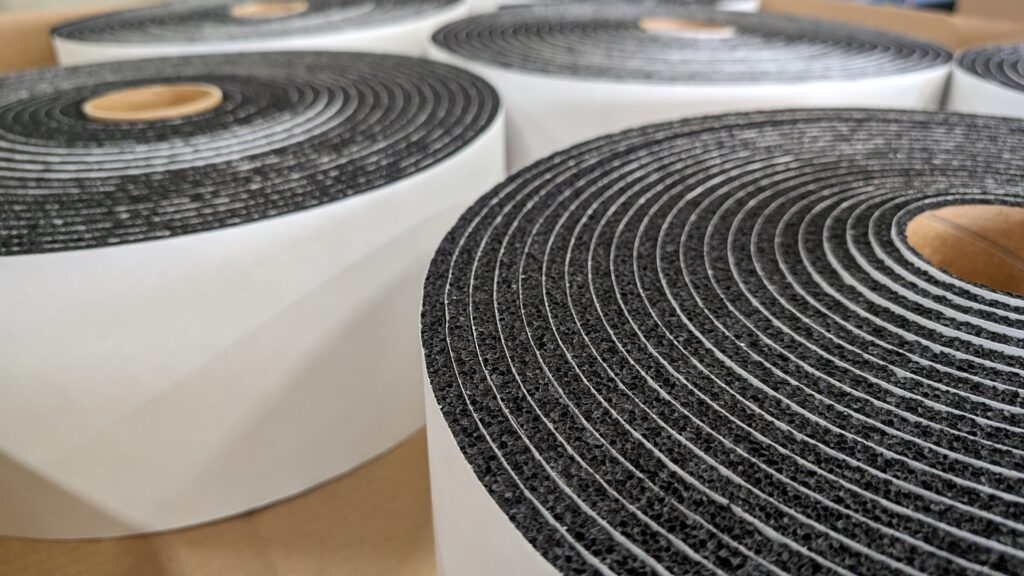

Slitting, Skiving, & Lamination

Del-Tec employs advanced slitting, roller splitting/skiving, and lamination techniques to create versatile and highly customized packaging solutions. Slitting precisely cuts materials into narrower widths, ideal for producing rolls or strips for various applications. Roller splitting, or skiving, operates by compressing the material between two rollers and feeding it through an ultra-sharp, fixed knife-edged blade. The material’s thickness is controlled by adjusting the roller distance and compression, allowing for precise, consistent results. This process excels in handling large-quantity jobs quickly and processing higher-density materials efficiently. Skiving reduces foam or plastic sheet thickness to achieve a perfect fit for lightweight or intricate applications. Lamination bonds multiple layers together, enhancing durability, insulation, or cushioning. Combined, these techniques allow us to deliver tailored packaging solutions with superior precision, performance, and quality.

Foam Saw Equipment

Del-Tec’s foam saw equipment is in place for precision cutting of many materials, but specialized for large-format polyurethane buns into manufacturable sheets and blocks. Our fleet of high-capacity saws, paired with material handling systems, ensures clean cuts, consistent thickness, and maximum material yield across every run. With years of experience controlling dimensions, we deliver foam components that are ready for downstream fabrication processes. This combination of equipment and expertise allows us to efficiently process small to large volumes while maintaining the accuracy, quality, and reliability your application demands.

Convoluting

Convoluting is a fabrication technique used by Del-Tec to create flexible and cushioned packaging materials. This process involves rolling and layering foam into spiral patterns, which enhances its shock absorption and protective qualities. Convoluted foam is commonly used in packaging delicate or fragile items, as the channels in the foam provide added cushioning and reduce movement during transit, ensuring maximum protection for your products.

PSA Application

Del-Tec utilizes Pressure-Sensitive Adhesive (PSA) application to create custom packaging solutions that offer enhanced convenience and functionality. PSA is a type of adhesive that bonds to surfaces with light pressure, without the need for heat or solvents. This technique allows for the easy attachment of foam inserts, cushioning materials, or protective films to various substrates, ensuring a secure fit for your products. PSA applications are ideal for creating packaging that is both easy to assemble and highly effective in protecting goods during transit, offering a cost-efficient solution for custom packaging needs.

Custom Case & Tote Assembly

Del-Tec specializes in custom case and tote assembly to provide reliable, organized, and durable packaging solutions. We design and assemble cases and totes tailored to your specific products, ensuring the perfect fit and maximum protection during transit. Whether you need sturdy plastic cases, stackable totes, or specialized compartments, our custom assemblies offer a seamless, efficient way to keep your items secure and easy to handle, making them ideal for both storage and shipping.

Sonic Welding

Our sonic welding technology utilizes high-frequency vibrations to create seamless connections in complex, multi-layered foam and plastic packaging. Del-Tec uses multiple (x8) Sonic Welders used to build totes, partitions, attach strapping, and we also weld various types of plastic.

Assembly & Kitting

Del-Tec offers assembly and knitting services as part of our turn-key packaging solutions, providing a seamless and integrated approach to meet your needs. Our skilled team assembles custom components, ensuring each packaging solution is fully functional and ready for use upon delivery. With knitting, we create flexible, strong connections between materials, ideal for complex or multi-part packaging systems. From design to final assembly, Del-Tec handles every step, delivering efficient, ready-to-use solutions that simplify your operations.

Quality Assurance

At Del-Tec, quality assurance is at the heart of every custom foam and plastic packaging solution we provide. We implement rigorous testing and inspection processes to ensure that each product meets the highest standards of durability, precision, and performance. From material selection to final assembly, our team ensures that every packaging solution is built to protect your products and optimize your supply chain. Del-Tec’s commitment to quality guarantees that you receive reliable, efficient, and effective packaging tailored to your exact specifications.