Foam Materials

XLPE - Cross-Linked Polyethylene

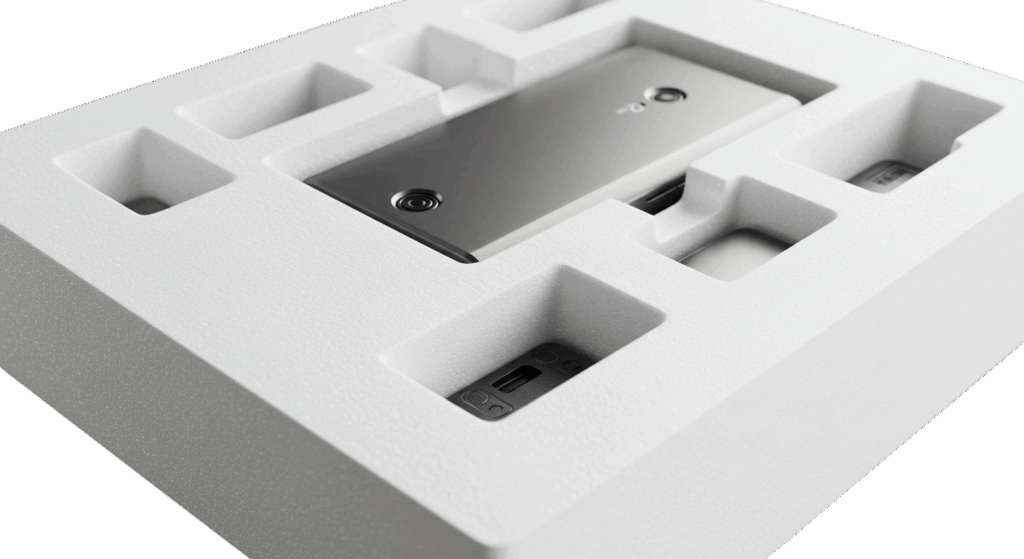

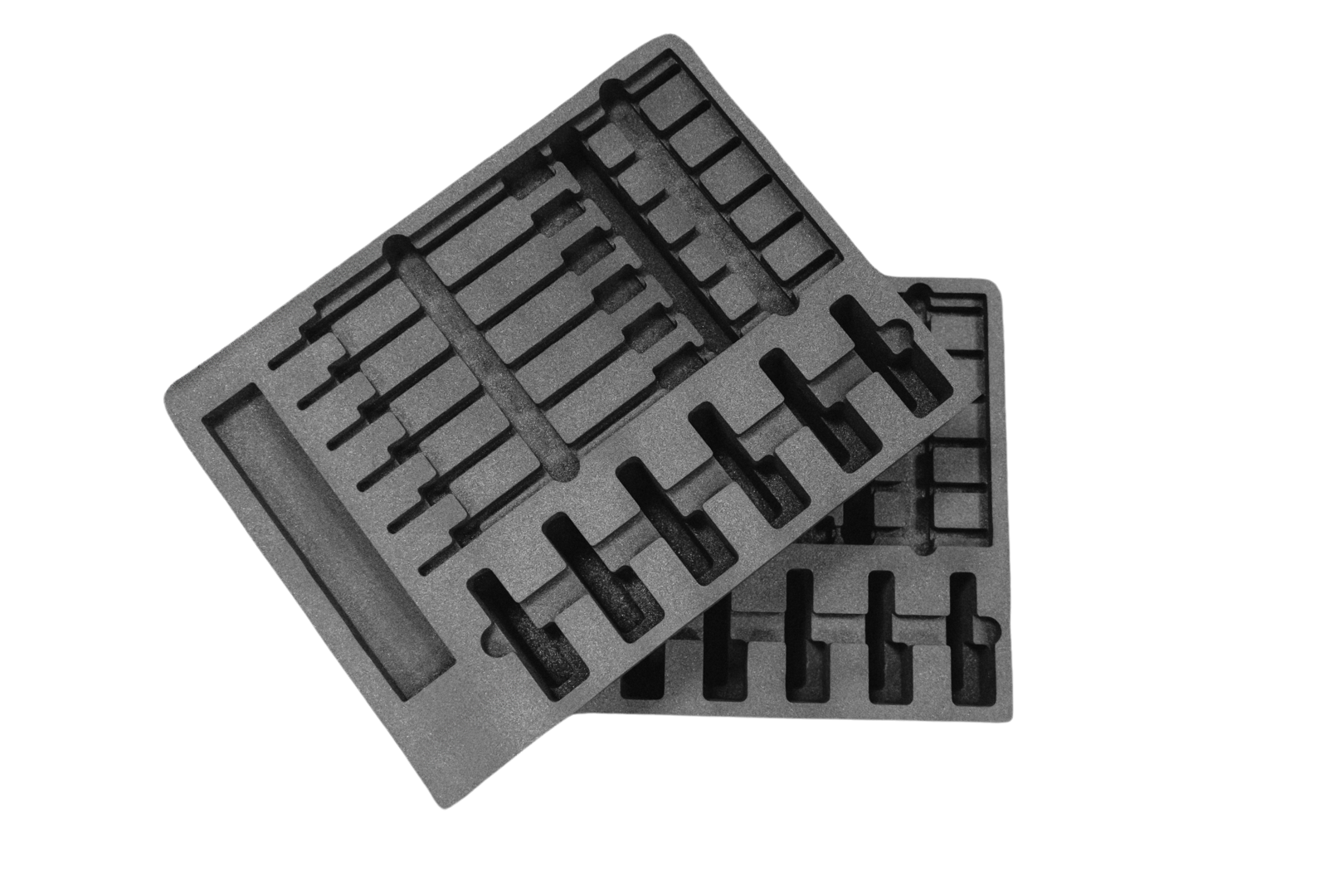

Cross-linked polyethylene (XLPE) is a versatile, durable foam material known for its excellent impact resistance, moisture resistance, and thermal insulation properties. Its closed-cell structure makes it lightweight yet robust, making it ideal for applications requiring cushioning and protection. Our products using XLPE are designed to safeguard delicate or high-value items during transport and storage, offering superior shock absorption and protection from environmental factors such as moisture and temperature fluctuations.

Technical Data

Density Range: 1.5# – 15.0#

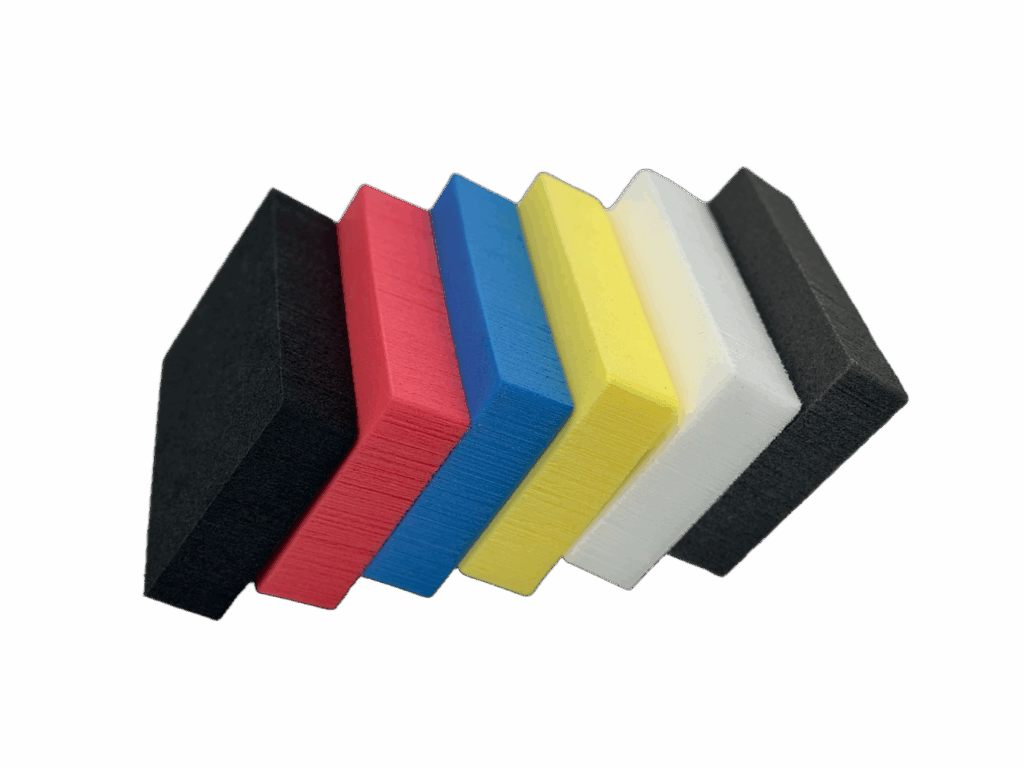

Colors: Wide Variety – See more info

Sizes: Wide Variety in Planks & Rolls

Creation Method: Chemically Cross-Linked – Molded & Extruded Foam

Features: Highly Flexible, Closed Celled, Smooth Surfaced, Chemical Resistivity, Shock Absorbing, & Durable Class A Material

Additives: ESD (Static Control) | Fire Retardant Meeting UL-94

More Information

Stocked Colors in Various Densities: Charcoal, Grey, Black, Red, Blue, Yellow, Green, & White

Strengths & Advantages: Class A. Excellent durability, resilience, compressive strength, shock absorption, chemical and moisture resistance, and dimensional stability. Minimal creep and good long-term performance.

Limitations: Harder to bond, often higher cost; less compressible/flexible than open-cell foams.

Typical Uses: Returnable protective packaging, Class A surface protective padding, Mil-Spec, case & tote dunnage, inserts, tool control, and shock absorbing applications.

PE - Polyethylene Foam

Del-Tec utilizes polyethylene foam in its packaging products to deliver lightweight, durable, and cost-effective solutions for protecting goods during transport and storage. This versatile material features a closed-cell structure, providing excellent cushioning, shock absorption, and resistance to moisture and chemicals. Del-Tec customizes polyethylene foam packaging to ensure optimal protection for delicate, high-value, or irregularly shaped items while maintaining an eco-friendly and reusable design.

Technical Data

Density Range: 0.9# – 9.0#

Colors: Wide Variety – See more info

Sizes: Wide Variety in Planks, Rolls, & Profiles

Creation Method: Extruded Foam

Features: Flexible, Open Celled, Lightweight, Recyclable, & Cost Effective Material

Additives: Anti-Static | Fire Resistance

More Information

Stocked Colors in Various Densities: Black, White, Pink, Grey, Blue, & Green

Strengths & Advantages: Good shock absorption, flexible, chemical and moisture resistant, ease of fabrication, cost-effective, and recyclable.

Limitations: At lower densities, lower compression load capacity; potentially less long-term stability under heavy loads; limited temperature extremes.

Typical Uses: Expendable & some Returnable packaging, end caps, cushioning, protective inserts, floatation, structural pads, general-purpose packaging.

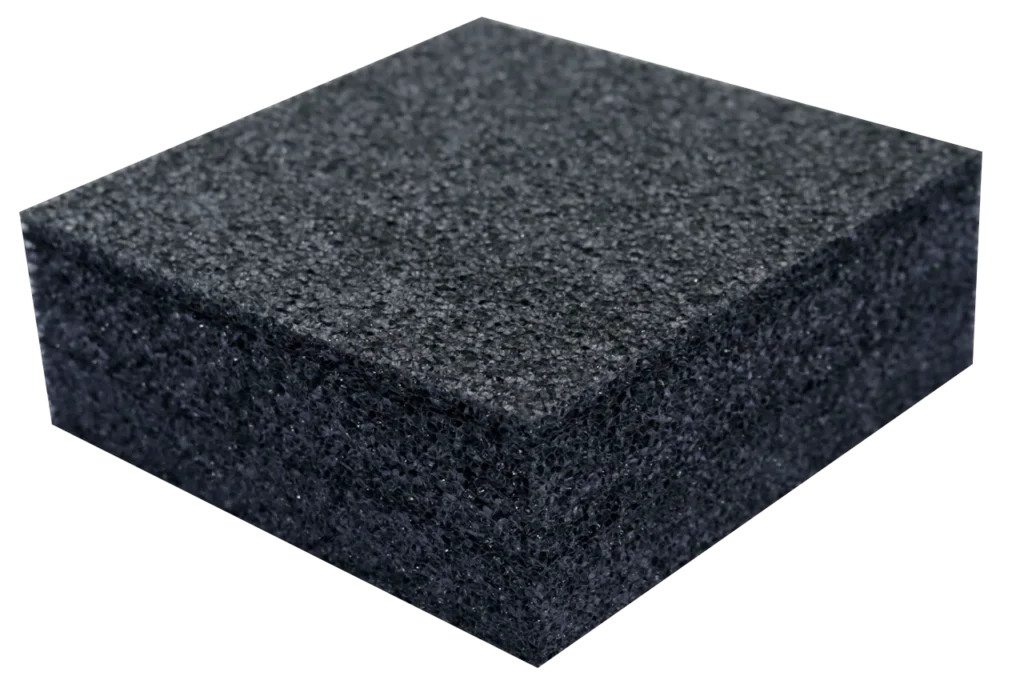

EPE - Expanded Polyethylene

Beaded or expanded polyethylene (EPE) is a lightweight, flexible, and resilient foam material with excellent shock absorption and cushioning properties. Its closed-cell structure resists moisture, chemicals, and physical stress, making it ideal for protecting fragile or sensitive items. EPE foam is also highly versatile and can be molded or cut into various shapes, offering tailored solutions for a wide range of packaging needs. Additionally, its reusability and recyclability contribute to sustainable packaging practices.

Technical Data

Density Range: 1.3# – 4.6#

Colors: Black & White

Sizes: 48 x 72 & 48 x 96 Planks

Creation Method: Molded Foam

Features: Highly Flexible, Closed Celled, Lightweight, Recyclable, Cost Effective, Shock Absorbing, & Durable Class A Material

Additives: Fire Retardant Meeting UL-94

More Information

Strengths & Advantages: Good shock absorption, very lightweight, great flexibility, moderate stiffness, chemical and moisture resistance, and cost-efficiency. Its bead structure gives some resilience and compressibility on all sides and handles long-term repeated compression.

Limitations: Not excellent durability, limited heat resistance, and average dimensional stability.

Typical Uses: Returnable & Expendable protective packaging, Class A surface protection padding, Mil-Spec, case & tote dunnage, inserts, & shock absorbing applications.

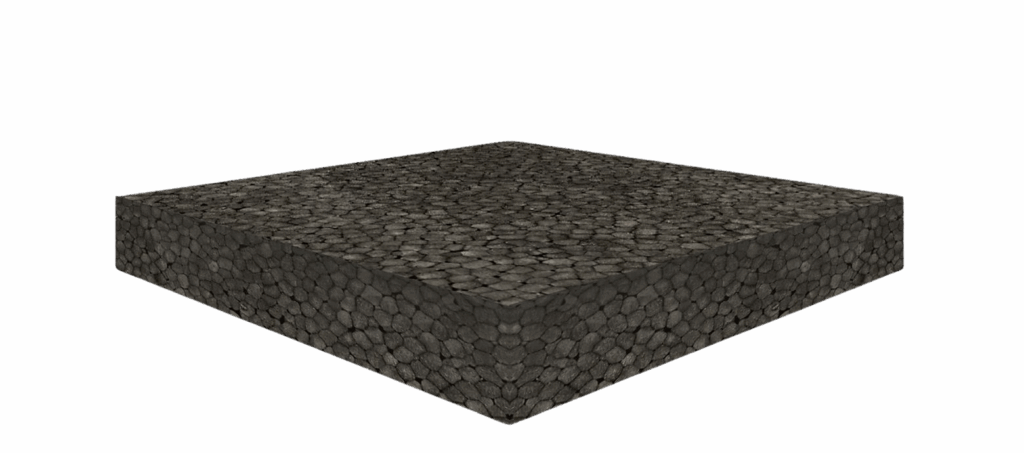

EPP - Expanded Polypropylene

Beaded or expanded polypropylene (EPP) is a lightweight, durable foam material known for its superior energy absorption, flexibility, and impact resistance. Its closed-cell structure makes it resistant to moisture, chemicals, and temperature fluctuations, ensuring long-lasting performance. EPP is widely used in packaging, automotive, and industrial applications due to its ability to provide exceptional protection for fragile or high-value items. Additionally, EPP is eco-friendly, as it is reusable and fully recyclable, making it an excellent choice for sustainable packaging solutions.

Technical Data

Density Range: 1.3# – 3.7#

Colors: Black & White

Sizes: 48 x 72 Planks

Creation Method: Molded Foam

Features: Very Rigid, Closed Celled, Excellent Insulator, Lightweight, Recyclable, Cost Effective, & Vibration Dampening.

Additives: Anti-Static | Fire Resistance

More Information

Strengths & Advantages: Very good energy absorption, repeated impact resiliency, lightweight, good thermal stability. Excellent for applications needing durability across multiple uses.

Limitations: Compressive stiffness, low flexibility & durability.

Typical Uses: Shock & Vibration Dampening Pallets, EV Battery Packs, Temperature Segregation, High Compression Void Fill, & Missile/Ordinance Dunnage.

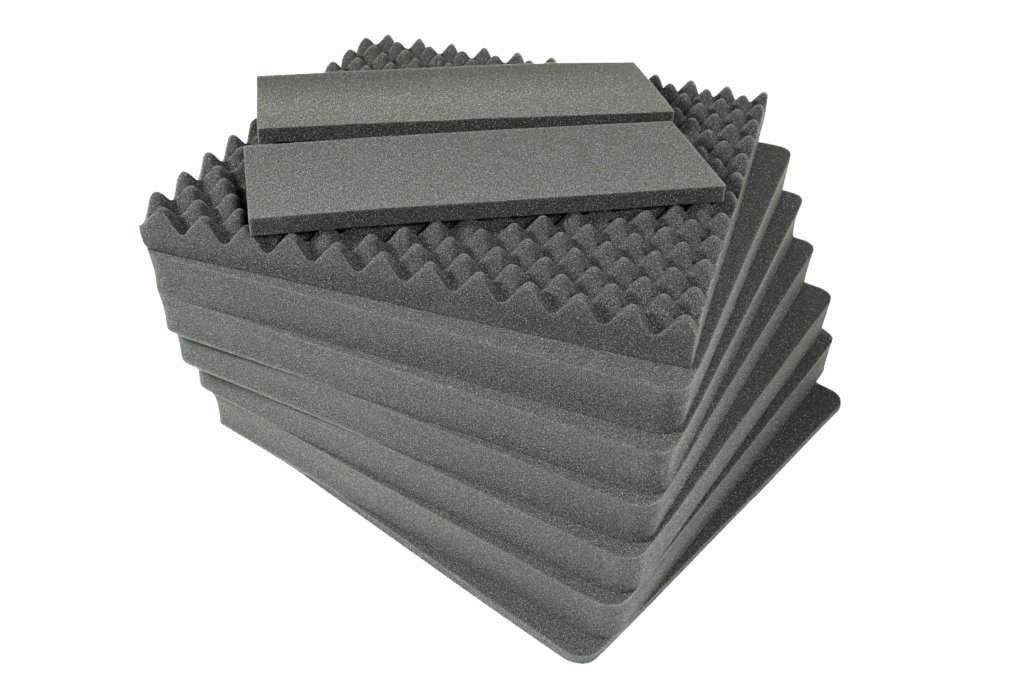

PU - Ether & Ester Polyurethane

Polyurethane foam is a versatile, resilient material known for its exceptional insulating properties, comfort, and structural integrity. Its open-cell or closed-cell configuration offers varying degrees of firmness, breathability, and moisture resistance, ensuring optimal performance across applications. Polyurethane foam is extensively utilized in furniture, bedding, automotive, and construction industries due to its ability to provide superior thermal insulation and sound dampening characteristics. Additionally, polyurethane foam can be formulated with bio-based components and recycled content, making it increasingly viable for environmentally conscious applications.

Technical Data

Density Range: 0.9# – 2.8#

ILD Range: 16# – 100#

“Identation Load Deflection”

Colors: Wide Variety – See more info

Sizes: Wide Variety Buns

Creation Method: Poured Foam

Features: Highly Flexible, Open Celled, Lightweight, Recyclable, & Cost Effective Material

Additives: Anti-Static | Fire Retardant

More Information

Stocked Colors in Various Densities: Charcoal, Light Grey, White, Pink, Blue, Red, & Yellow

Strengths & Advantages: Excellent energy absorption, highly flexible, sound dampening, and custom formulations for varied firmness or resilience.

Limitations: Open-cell forms may absorb moisture; less chemical resistance; lower density can degrade over time under UV or oxygen exposure, delicate under heavy compression.

Typical Uses: Expendable & generic packaging, furniture upholstery, acoustic dampening, medical cushioning, soft inserts, and anti-microbial.

EPS - Expanded Polystyrene

Expanded Polystyrene (EPS) offers numerous benefits, including excellent thermal insulation, making it ideal for packaging, construction, and food service applications. Its closed-cell structure provides effective moisture resistance, making it suitable for long-term storage and transportation of sensitive items. Lightweight yet strong, Expanded Polystyrene offers superior impact protection and dimensional stability, making it a practical choice for protective packaging, building insulation, and disposable food containers.

Technical Data

Density Range: 0.75# – 3.0#

Colors: White

Sizes: Wide Variety Custom Molded Parts & Billets

Creation Method: Molded Foam

Features: Very Rigid, Closed Celled, Lightweight, & High Thermal Resistance

More Information

Strengths & Advantages: Very lightweight, excellent thermal insulation, and cost effective at large quantities.

Limitations: Lower structural strength compared to engineered foams; susceptible to certain solvents; less durable under heavy mechanical load over time

Typical Uses: Insulation boards & coolers, expendable packaging blocks & corners, and one-way shipping protection.

ESD - Zote - Filter - gasket Foams & Rubbers

Del Tec Packaging offers a diverse range of high-performance materials including specialized foams, durable plastics, and sustainable paper options. Each material is selected for its unique protective properties, enabling us to create customized packaging that balances protection, sustainability, and cost-effectiveness for your specific needs.

Anti-Static & Conductive

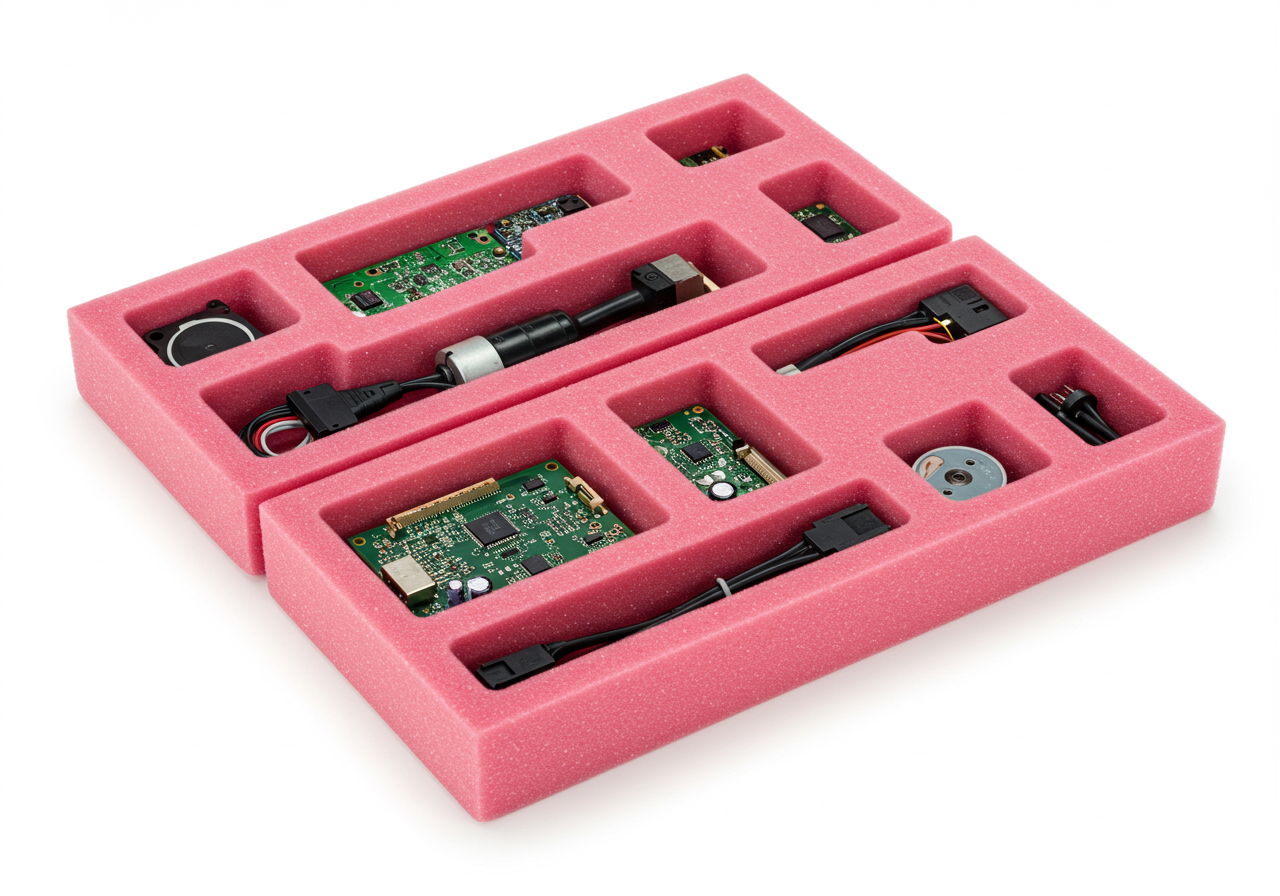

Anti-Static & Conductive materials in custom packaging provide reliable protection for sensitive electronics by safely channeling electrostatic discharges (ESD) away from devices. With a low-resistance surface, they allow electrical currents to flow through the material and ground potential threats. Ideal for circuit boards, semiconductors, and other high-risk components, conductive packaging ensures damage-free transport and storage in static-sensitive environments.

Technical Data

Density Range: 0.9# – 9.0#

Colors: Wide Variety – See more info

Sizes: Wide Variety in Planks, Rolls, & Profiles

Creation Method: Extruded Foam

Features: Flexible, Open Celled, Lightweight, Recyclable, & Cost Effective Material

Additives: Anti-Static | Fire Resistance

More Information

Stocked Colors in Various Densities: Black, White, Pink, Grey, Blue, & Green

Strengths & Advantages: Good resilience, chemical and moisture resistance, ease of fabrication, cost-effective, recyclable.

Limitations: At lower densities, lower compression load capacity; potentially less long-term stability under heavy loads; limited temperature extremes.

Typical Uses: Expendable & Some Returnable packaging, cushioning, protective inserts, floatation, structural pads, general-purpose packaging.

Zotefoam

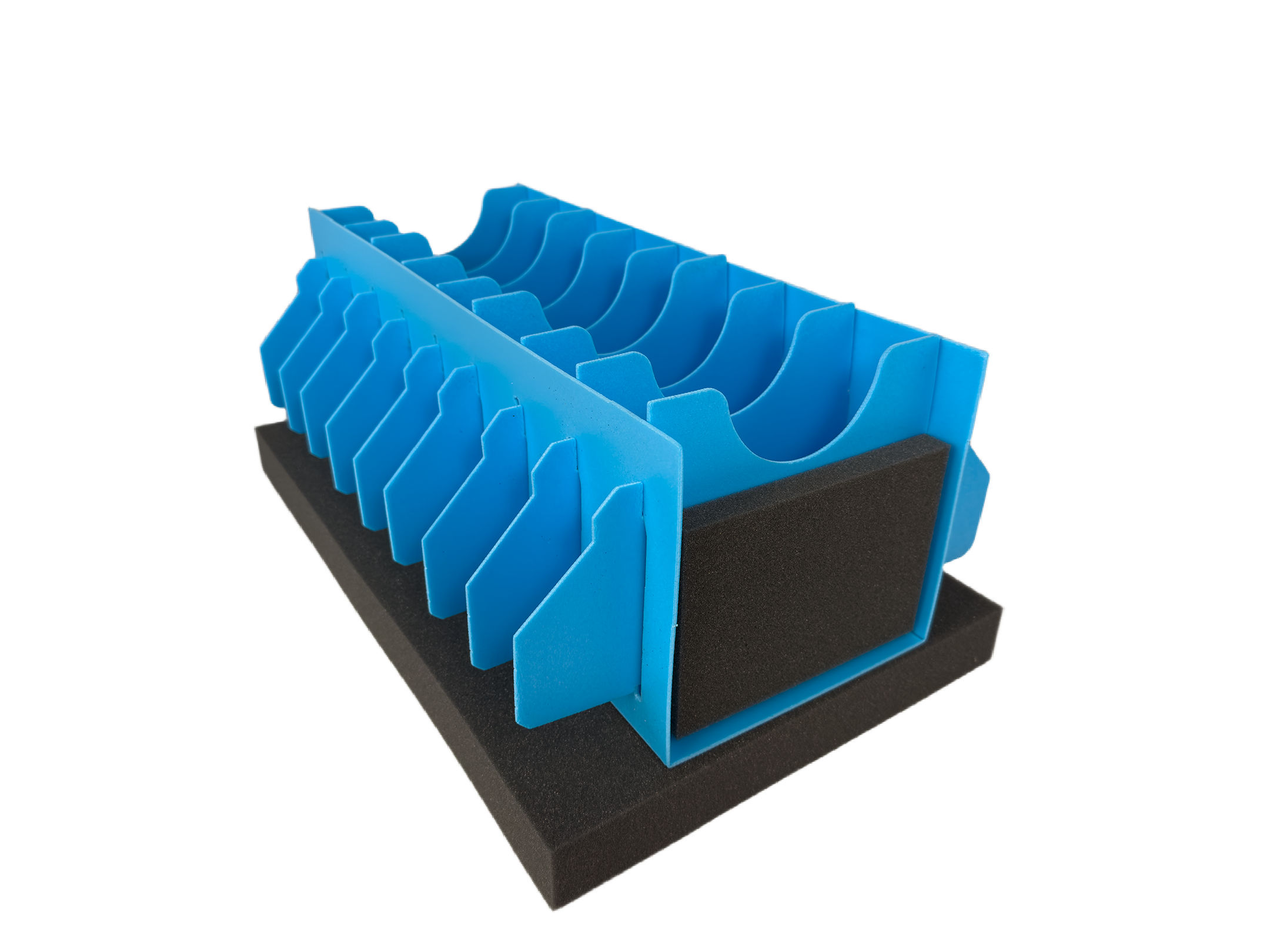

Zotefoam is a premium, closed-cell foam renowned for its lightweight, durable, and highly customizable properties. Manufactured using a unique nitrogen expansion process, Zotefoam offers superior consistency, resilience, and resistance to chemicals, moisture, and temperature fluctuations. Its versatility makes it ideal for a wide range of applications, including protective packaging, automotive components, and medical devices. Additionally, Zotefoam is eco-friendly, as it is reusable, recyclable, and produced with minimal environmental impact.

Technical Data

Density Range: 1.0# – 6.0#

Colors: Wide Variety – See more info

Sizes: Wide Variety in Planks

Creation Method: Molded Foam

Features: Highly Flexible, Closed Celled, Smooth Surfaced, Chemical Resistivity, Shock Absorbing, & Durable Class A Material

Additives: Anti-Static | Fire Resistance

More Information

Stocked Colors in Various Densities:

Strengths & Advantages: Outstanding durability, chemical resistance, dimensional stability, broad fabrication capabilities, excellent for repeated-use dunnage.

Limitations: Higher cost relative to open cell or semi-rigid foams; cutting/fabricating may require more advanced equipment.

Typical Uses: High-cycle reusable packaging, protective dunnage, aerospace inserts, and technical cushioning.

Worldcell

Anti-static ESD materials in custom packaging prevent the buildup of static electricity on surfaces, reducing the risk of sudden electrostatic discharge. By dissipating charges before they accumulate, they safeguard sensitive electronics, such as semiconductors and circuit boards, from damage. Lightweight and effective, anti-static packaging is ideal for protecting products during handling, transport, and storage in static-sensitive environments.

Technical Data

Density Range: 0.9# – 9.0#

Colors: Blue & Custom Black

Sizes: 48 X 96 Sheets & Custom Widths

Thickness: 2-5 MM

Creation Method: Extruded Foam

Features: Flexible, Closed Celled, Lightweight, Manipulatable, Class A Smooth Surface & Cost Effective Material

Finishes: Spunbond

More Information

Strengths & Advantages: Lightweight structural board, good stacking strength, & moisture resistant.

Limitations: Higher cost relative to plastic corrugated

Typical Uses: Dividers, partitions, bulk-bin liners, & light structural shipping containers