Plastic Materials

PCORR - Polypropylene Corrugated

PCORR is a lightweight, durable plastic material. Known for its impact resistance, moisture resistance, and versatility, it provides excellent protection for a variety of items during transport and storage. This material is easy to cut, fold, shape, and add print making it ideal for creating tailored packaging designs. Additionally, polypropylene corrugated is reusable and recyclable.

Technical Data

Thickness Range: 2mm – 10mm

Standard Colors: Black, White, Light Blue, Natural, & Light Gray

Standard Sizes: 48″ x 96″ & Custom

Creation Method: Extruded

Features: Lightweight, excellent moisture resistance, durability in rough handling, reusable possibilities

Additives: Conductive & Anti-Static

Class A Laminations: Spunbond & Brushed Nylon

More Information

Premium Colors: Yellow, Green, Red, Orange, Silver, Purple, Brown, Medium Blue & Navy Blue

Custom Sizes: Various Available

Strengths & Advantages: Lightweight, excellent moisture resistance, durability in rough handling, reusable possibilities

Limitations: Less cushioning than foam; increased dimensional weight compared to minimal foam.

Typical Uses: Dividers, shipping totes, boxes, reusable crates, & reel packaging

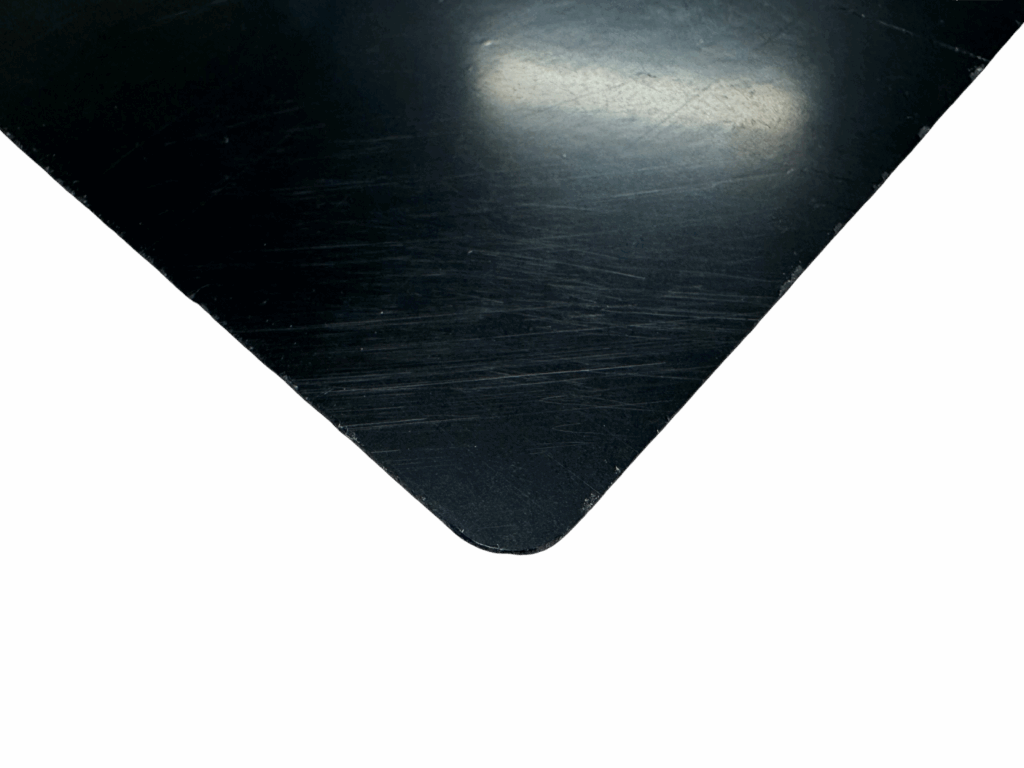

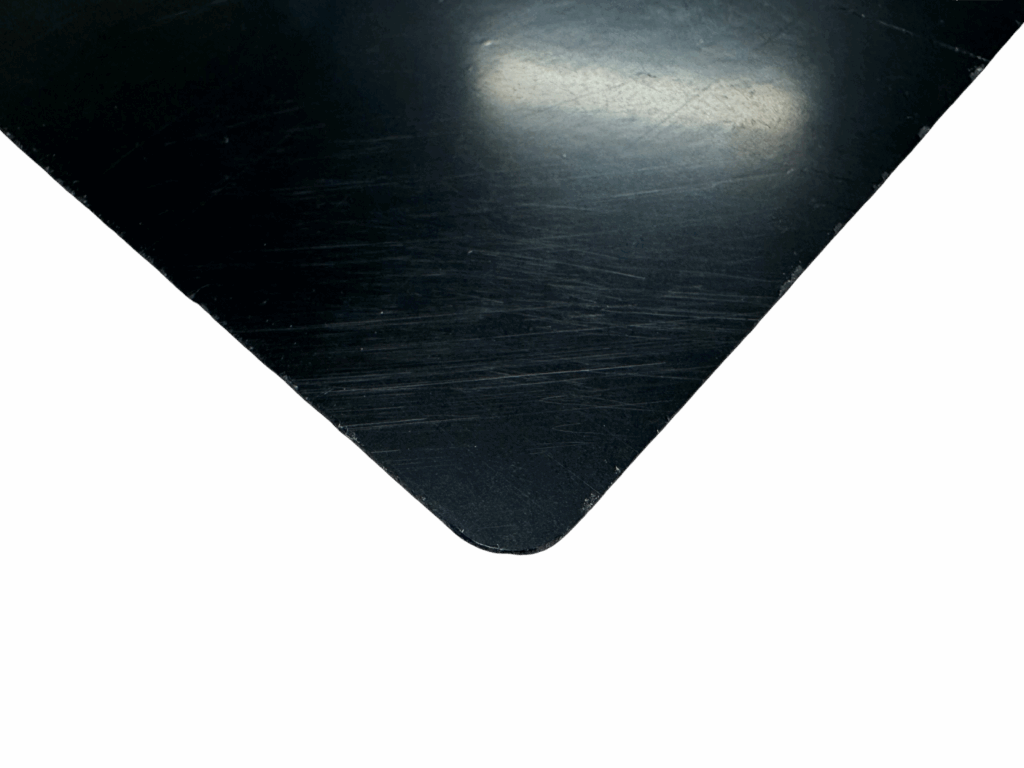

HDPE - High-Density Polyethylene

HDPE is a durable and lightweight material typically used in custom packaging, as it provides excellent impact resistance, moisture barrier properties, and chemical durability. It protects products from damage during transit and storage while resisting cracking or abrasions. HDPE is an excellent choice for industrial, medical or food products for long-lasting, reliable packaging protection in a variety of environments.

Technical Data

Standard Thickness Range: 0.03″ – 0.50″

Standard Colors: Black, Natural, Red, Yellow, Green, & Beige

Standard Widths & Lengths: 12″ | 24″ | 48″ | 96″

Creation Method: Extruded

Features: Easy to Fabricate & Weld, Sleek Finish & Low Friction, & Good Electrical Insulation

Resistant to Abrasion, Chemicals, Hydrolysis, Impacts, Moisture, Stain & Wear

Common Profiles: Sheets, Rods, Tubes & Film

More Information

Custom Sizes: Various Available

Strengths & Advantages: Rugged structural strength, & good resistance to externals

Limitations: Heavy weight, less compressive, non-absorbent cushioning; machining takes more time

Typical Uses: Structural components, dividers, reinforced dunnage, rigid inserts, & tray bases

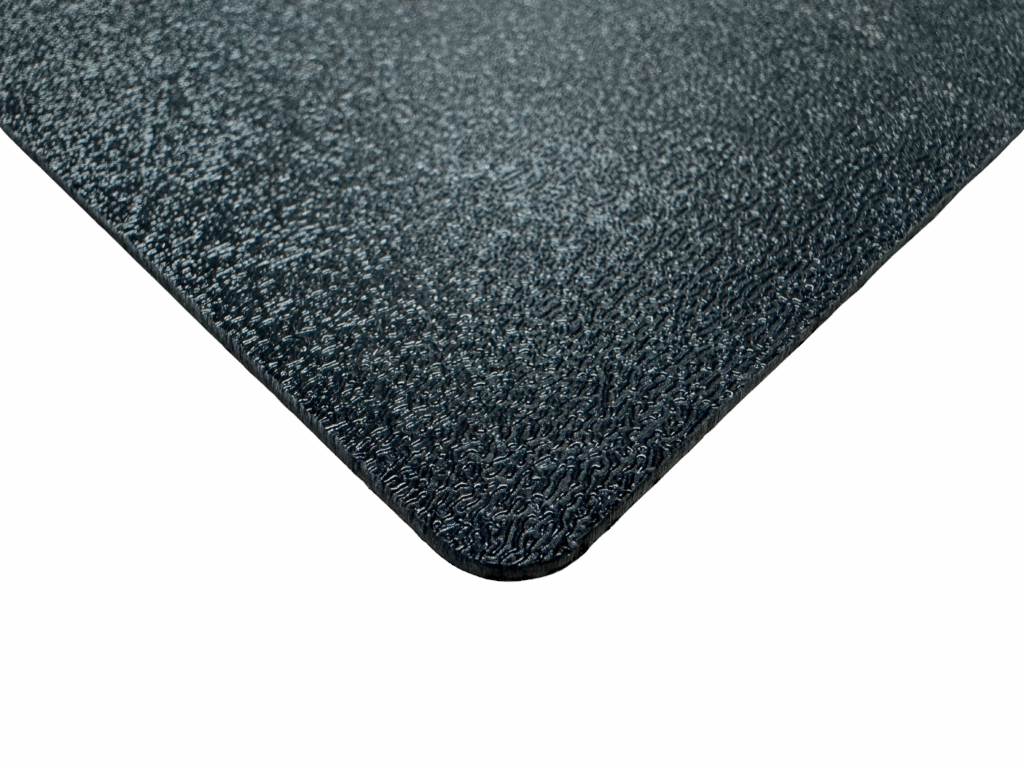

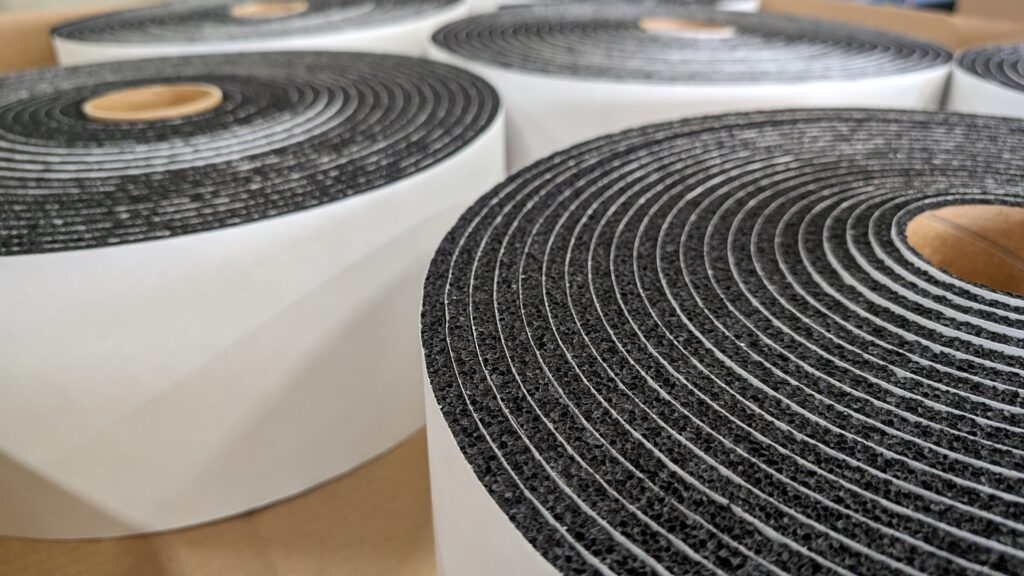

LDPE - Low-Density Polyethylene

LDPE is both flexible and lightweight, and it is commonly used in packaging products due to its excellent cushioning, impact absorption and moisture resistance. With its pliability, it can conform to different product shapes, which provides reliable protection. LDPE is a great choice for protective films, wraps and bags.

Technical Data

Standard Thickness Range: 0.03″ – 0.50″

Standard Colors: Black, Natural, Red, Yellow, Green, & Beige

Standard Widths: 36″ | 48″ | 60″

Standard Lengths: 36″ | 48″ | 60″ | 96″

Creation Method: Extruded

Features: Easy to Fabricate & Weld, Sleek Finish & Low Friction, Good Electrical Insulation, Resistant to Abrasion, Chemicals, Hydrolysis, & Impacts

Common Profiles: Sheets, Rods, Tubes, & Film

More Information

Custom Sizes: Various Available

Strengths & Advantages: Good flexibility, cost-effective, easy to fabricate, good for packaging that needs conformability

Limitations: Lower stiffness/strength than HDPE, less ideal for heavy load applications

Typical Uses: Partitions, dunnage, protective wraps & rolls, light cushioning, & flexible liners

ABS - acrylonitrile Butadiene Styrene

ABS is a tough, impact-resistant plastic commonly used in packaging products for its durability and versatility. Its lightweight yet strong structure provides excellent protection for items during handling and transportation. ABS is also resistant to chemicals and temperature fluctuations, making it suitable for demanding environments. With its smooth surface and customizable properties, ABS is ideal for creating reusable, protective packaging solutions that combine functionality with a polished appearance.

Technical Data

Standard Thickness Range: 0.03″ – 0.50″

Standard Colors: Black, Natural, White, & Gray

Standard Widths: 24″ | 48″

Standard Lengths: 96″ | 120″

Creation Method: Extruded

Features: Easy to Fabricate & Bond, Good Dimensional Stability & Electrical Insulation

Resistant to Abrasion, Impacts, Moisture, & Wear

Common Profiles: Sheets, Rods, & Tubes

More Information

Strengths & Advantages: Good structural rigidity, impact resistance, ease of machining/thermoforming, excellent finish

Limitations: Heavier per volume than plastic; minimal inherent cushioning; cost can be higher

Typical Uses: Case Components, Export Cases, Pallets, Molded Tote Components, & Rugged Housings

Polycarbonate

Polycarbonate is a highly durable and impact-resistant plastic that is ideal for custom packaging solutions. Known for its strength, transparency, and lightweight nature, it provides excellent protection for delicate or high-value items while allowing visibility of the contents. Its resistance to heat, UV light, and chemicals makes it suitable for demanding environments. Polycarbonate can be molded and shaped into various designs, offering versatile and reusable packaging options tailored to specific needs.

Spec Sheets

PVC

Del-Tec uses PVC (Polyvinyl Chloride) for packaging products due to its exceptional durability, versatility, and resistance to moisture, chemicals, and impact. PVC’s lightweight yet sturdy structure makes it ideal for protecting items during transport and storage, especially in demanding environments. Its ability to be molded, cut, or shaped into custom designs ensures tailored solutions for unique packaging needs. Additionally, PVC’s longevity and reusability make it a cost-effective and reliable choice for protective packaging applications.