Specialty Foams & Plastics

Del-Tec’s specialty foam solutions are engineered for applications where off-the-shelf materials won’t do. When parts are delicate, mission-critical, or require precise environmental control, we combine premium foams with automated fabrication like CNC, waterjet, routed, die cut, molding, and lamination to deliver drawer inserts and tool-control systems, filtration media, gasket and sealing components, and molded thermal packaging. Each solution is specified to the application and backed by quick prototyping, rigorous QA, material selection expertise, and automated production. Del-Tec’s specialty foams protect sensitive surfaces and extend equipment life across aerospace, medical, electronics, and industrial programs.

Drawer Inserts & Tool Control

Del-Tec’s tool control and drawer insert systems generally utilize high quality cross-linked and extruded polyethylene along with other high-performance foams to maintain order, precision, and accountability in tooling environments. Each insert is CNC-cut to exact cavity tolerances, securing each tool in place while offering visual cueing with vibrant colors to highlight missing pieces. Typical tool control will have a layer of black or charcoal foam assembled to a bright colored foam behind it to show when a tool is missing from the set. With these solutions, we can deliver customized layouts to accommodate any type of tool set whether it’s for mobile tool kits, production tooling, service carts, or aerospace/machinery repair sets.

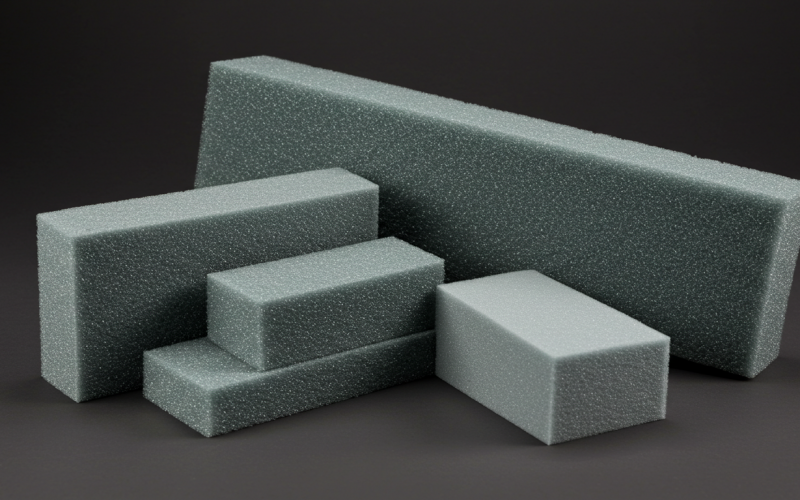

Filter Foam

Our reticulated filter foam employs an open-cell architecture with controlled pore sizes to deliver consistent air/fluid flow while capturing particulates. These specialty foams perform reliably in fluid filtration settings, dust collection systems, and ventilation. Available in multiple pore sizes and densities, our materials outperform conventional methods in demanding filtration and environmental control applications.

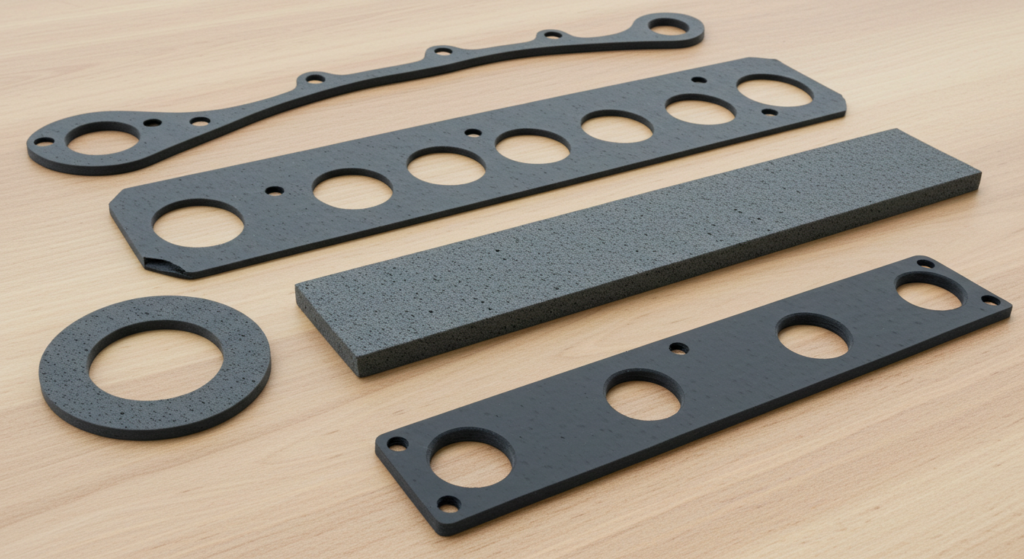

Gasket Foam & Rubber

For demanding sealing challenges in harsh or variable environments, Del-Tec provides gasket solutions using rubber, neoprene, cross-linked polyethylene foams. These custom-cut seals offer compression retention, consistent performance across temperature and humidity swings, and resistance to ozone, UV, and chemical exposure. Ideal for protecting against moisture ingress, dust contamination, and vibration in enclosures, instrumentation, and transportation systems.

Thermal Foam Packaging

Del-Tec’s molded thermal foam packaging combines the insulation of expanded polystyrene and the resilience of expanded polypropylene to protect temperature-sensitive products with minimal weight. Engineered through precision molding and fabrication, these one-piece trays, lids, and block systems deliver consistent thermal performance, structural impact resistance, and cross-stack strength for high-volume runs. We optimize bead density, wall thickness, and part geometry to balance insulation, cushioning, and freight efficiency, reducing dimensional weight while maintaining temperature integrity. Custom inserts and multi-layer assemblies are available to meet specific product and project requirements, ensuring reliable protection throughout transit.