Safety Data

Beaded Expanded Polyethylene

Expanded Polyethylene

Foam for Custom Packaging Solutions

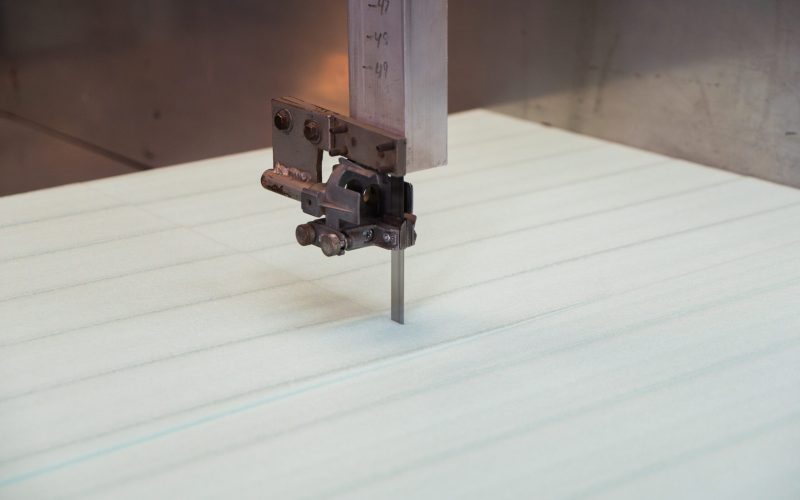

At Del-Tec, we utilize Expanded Polyethylene (EPE) foam as a versatile material in fabricating custom packaging solutions for businesses across various industries. EPE foam’s unique properties make it an ideal choice for protecting products during transportation, storage, and handling.

What is EPE Foam?

EPE foam is produced by expanding polyethylene resin into beads, which are then block-molded into planks under controlled heat and pressure. This process creates a closed-cell, isotropic structure that provides excellent shock absorption, dimensional stability, and impact resistance in all directions.

Expanded Polyethylene

Strengths & Weaknesses

- Strengths

- Lightweight: Offers a lightweight solution for various applications.

- Shock Absorption: Provides excellent shock absorption properties.

- Flexibility: Highly flexible, accommodating various design requirements.

- Weaknesses

- Lower Thermal Resistance: Not as effective in high-temperature applications compared to some other foams.

Applications

- Packaging: Commonly used for protective packaging due to its cushioning properties.

- Flotation Devices: Applied in buoyancy applications, such as life vests and floating mats.

- Cushioning Materials: Used in applications requiring impact resistance and lightweight cushioning.

- Automotive Rack Dunnage

- Case Inserts

- Crate Liners

- Electronics Packaging

- Expendable Dunnage

- Gaskets